CHRONOMETRIC PRECISION

-3/+5 seconds per day chronometric performance and high resistance to magnetic fields and shocks.

70 HOURS POWER RESERVE

Increased power reserve thanks to a large barrel allowing optimized winding while preserving a frequency of 28,800 A/h (4Hz).

OWN DESIGN LOCALLY MANUFACTURED

The Calibre Manufacture Morteau 10 (CMM.10) unique’s design offers high performance thanks to its modern architecture and high-quality Franco-Swiss components. Entirely designed and developed by YEMA, the regulating organs are manufactured in Switzerland while the mainplate and bridges are manufactured by YEMA in its Morteau workshops.

MODERN ARCHITECTURE

The CMM.10 offers a modern take on traditional 3-hands calibers. The construction of the transversal bridge over the balance wheel provides stability, a circular cut-out in the mainplate elegantly frames the balance wheel, permitting views of the regulating organ. The mainplate symmetrical architecture ensures a perfect and elegant vertical alignment of the balance wheel and large barrel.

Moreover, the CMM.10 features a central bridge design that combines the barrel bridge, center wheel bridge and winding stem cock into a large single bridge that forms the central pillar of the movement. This structure reduces the number of bridges and reinforces the main plate by making it possible to contain most of the gear train within the structure, the movement overall enjoys significantly better strength, durability and shock resistance

BALANCE WHEEL TRANSVERSAL BRIDGE

The elegant and modern architecture of the balance wheel transversal bridge, with its two fixing points, guarantees high positioning precision. This double bridge helps ensure the stability, shock resistance and precision of the balance wheel whatever the intensity of the activities carried out.

HIGH SHOCK RESISTANCE

The ultra-precise geometry of the Incabloc® double-cone shock absorbers transform uncontrolled shocks of all magnitudes and coming from any direction into movements rigorously directed perpendicular to the balance axis, thus ensuring incomparable robustness to the CMM.10 regulator mechanism.

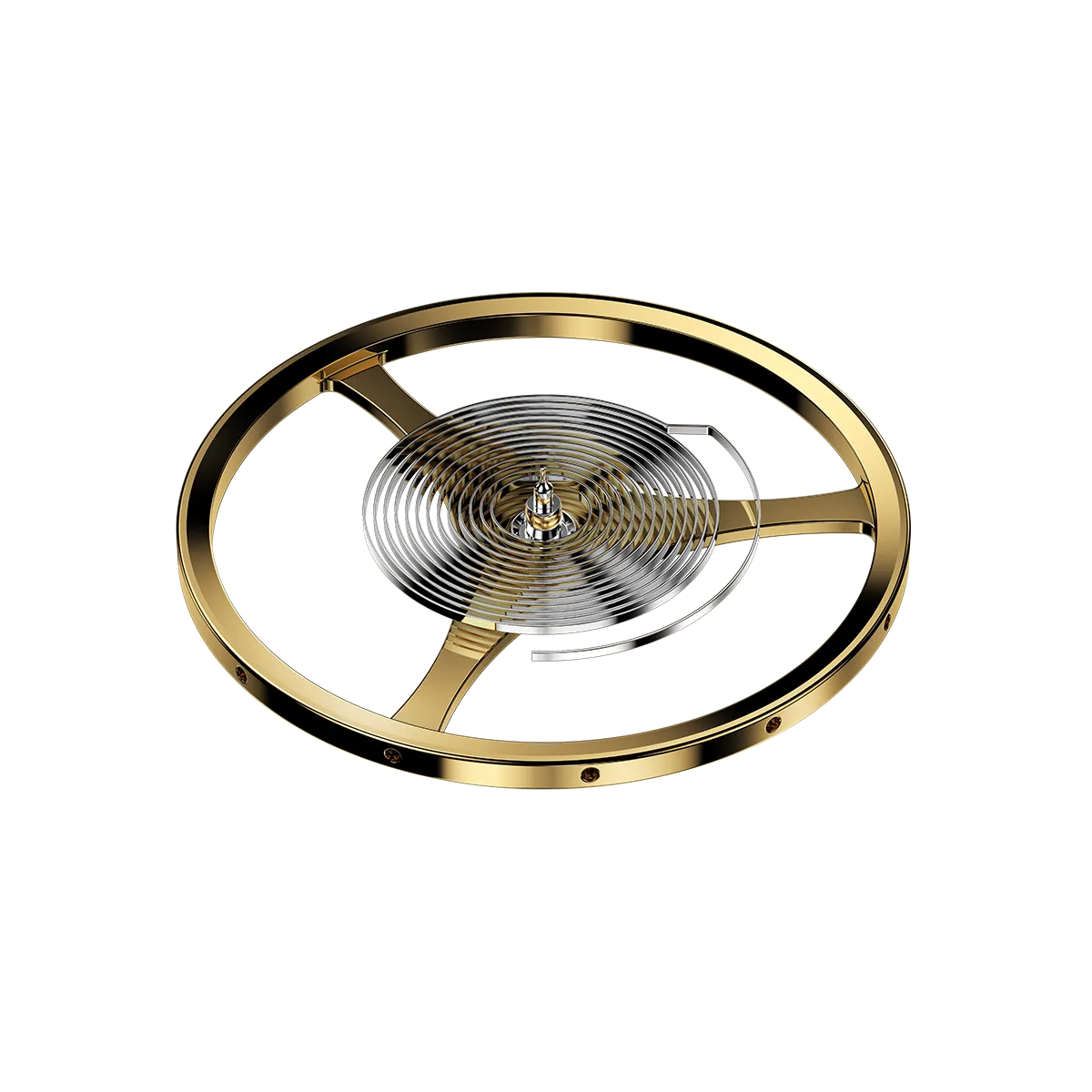

GLUCYDUR BALANCE WHEEL HIGH ACCURACY

The balance wheel is made of Glucydur, a non-magnetic metal alloy with low thermal expansion that provides greater resistance to deformation, corrosion, and magnetic fields. Glucydur is the optimal alloy for the balance wheel which requires stability. The Nivarox® hairspring has high resistance to temperature changes and contributes to the continuous precision of the regulating organ.

70 HOURS OF POWER RESERVE THANKS TO A LARGE BARREL

The CMM.10 caliber has a single large barrel manufactured by Générale Ressorts, optimized to ensure a power reserve of 70 hours while preserving a high frequency of 28,800A/h (4Hz). The Nivaflex® barrel spring alloys combine excellent mechanical properties with excellent corrosion resistance, non-magnetic behavior and a very low coefficient of thermal expansion.

OPTIMIZED ESCAPEMENT

Interface between the gear train and the regulating organ, the escapement is the place where energy and chronometry intersect in a complex interaction. The escapement is an energy-demanding system, it alone consumes more than half of the barrels’ energy. It is the friction of the anchor pallets on the anchor which, despite their lubrication, dissipates a good part of this energy. The CMM.10 escapement presents notable improvements which reduce this friction thanks to a sophisticated manufacturing process. This advanced escapement ensures optimization of the entire mechanics, precision, and longevity of the caliber components.

SMOOTH AUTOMATIC WINDING MECHANISM

The bidirectional oscillating weight allows the mechanism to be automatically wound using the kinetic energy produced by the wearer's movements. Whatever the direction of rotation of the oscillating weight, it operates by charging the large spring barrel which, once fully wound, offers 70 hours of autonomy. The oscillating weight is mounted on optimized ball bearings that are very resistant to wear and minimize friction, rotate smoothly and silently. Engraved with the words CALIBRE MANUFACTURE MORTEAU 10 and decorated in a “gunmetal” finish in contrast with the galvanized black bridges, the design of the oscillating weight reinforces the innovative and contemporary aesthetic of the caliber.

CLEAN CONTEMPORARY AESTHETIC

The CMM.10 was designed as an innovative, new generation, high performance caliber. In order to reinforce the contemporary appearance of the caliber we have opted for a modern and differentiating aesthetic with black galvanic decoration of the bridges and plate. The micro blasting treatment of the mainplate and bridges, applied with a sand blasting machine, results in a neutral, matt surface finish in contrast with the oscillating weight "gunmetal" finish. The uniform black galvanic coating preserves the decorative micro blasting finish of the surface.

TALENTED FRENCH WATCHMAKERS TEAM

Four talented French watchmakers, cumulating over 120 years experience at the most prestigious watch brands, have taken up the challenge of creating YEMA’s first Manufacture Caliber

YEMA'S IN-HOUSE WATCHMAKING MACHINING CENTER

During the last two years, YEMA has made substantial investments aimed at insourcing a good part of its production, constantly improving the quality of the manufacturing processes as well as developing a future range of French Manufacture calibers.

This significant development has required substantial R&D, new equipment and the expansion and modernization of our workshops and production lines. YEMA’s Manufacture Calibers benefit from improved precision and performance and will soon equip premium YEMA timepieces.

LOCAL PRODUCTION

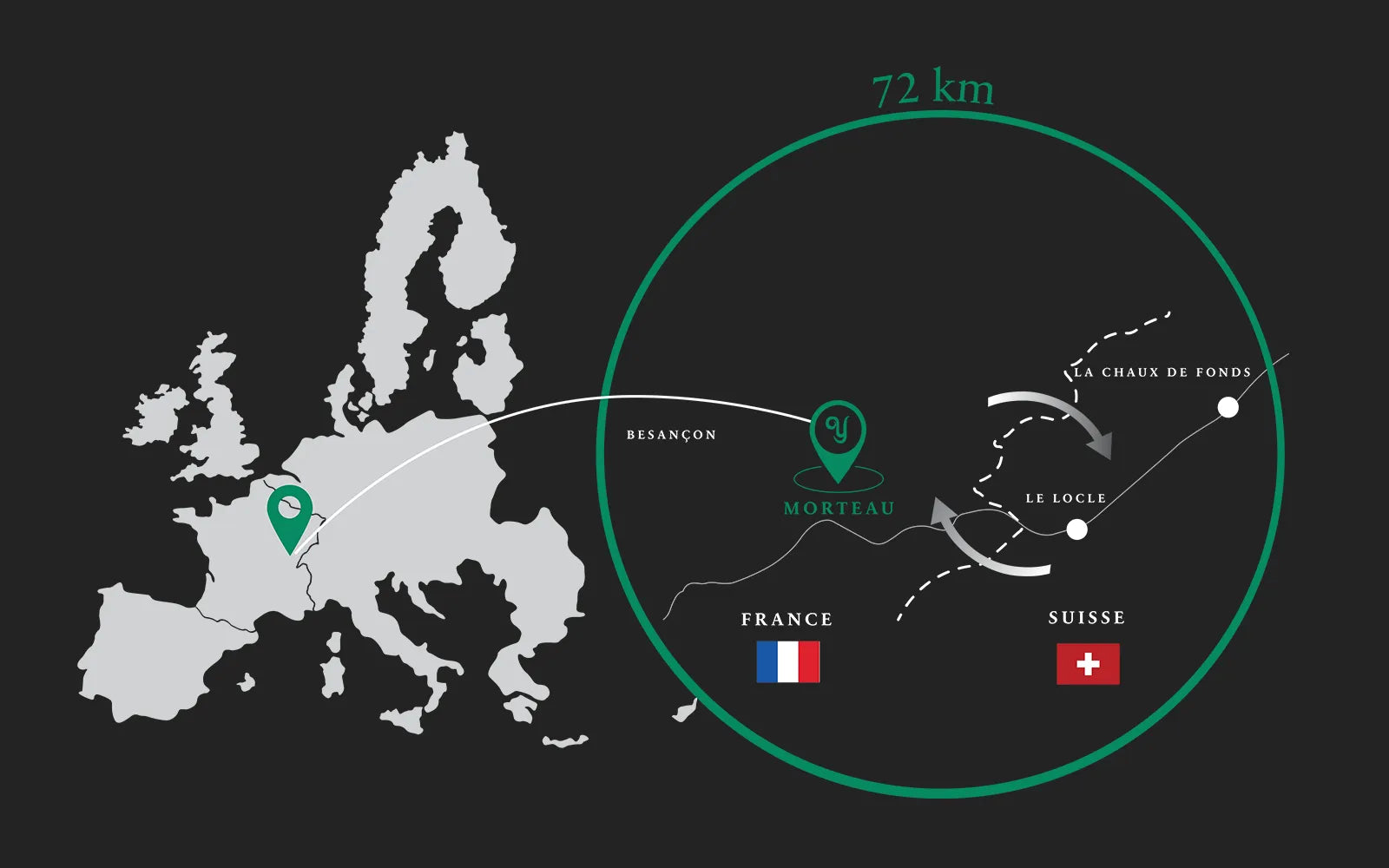

Over the past few years, YEMA has made significant investments aimed at insourcing a good part of its production and constantly improving the quality of its manufacturing processes by implementing latest equipment as well as expanding and modernising its workshops and production lines.

In addition, YEMA now works with new local partners in France and Switzerland within a range of 72km of its workshops, to secure a more responsible and higher quality production.

Movement Components

All Manufacture movement components are manufactured in France and Switzerland within a range of 72km from Morteau by recognized craftsman in fine watchmaking. The caliber bridges and mainplates are manufactured in YEMA’s workshops in Morteau where final assembly of all components takes place.

COMPONENTS

ORIGINS

Movement Design

France

Movement Components

France + Switzerland

Assemblies

France

A DYNAMIC REGIONAL WATCHMAKING ECOSYSTEM

YEMA workshops are based in Morteau, the cradle of French watchmaking, a few steps from the Swiss watchmaking region. This cross-border watchmaking community concentrated along the Jura mountains has gradually transformed into a true regional ecosystem recognized as Intangible Cultural Heritage by the UNESCO in 2020.