-3/+7 SECONDS ACCURACY

Near chronometric performance and high resistance to magnetic fields and shocks.

70 HOURS POWER RESERVE

Enhanced power reserve thanks to innovating Tungsten micro-rotor and a large barrel.

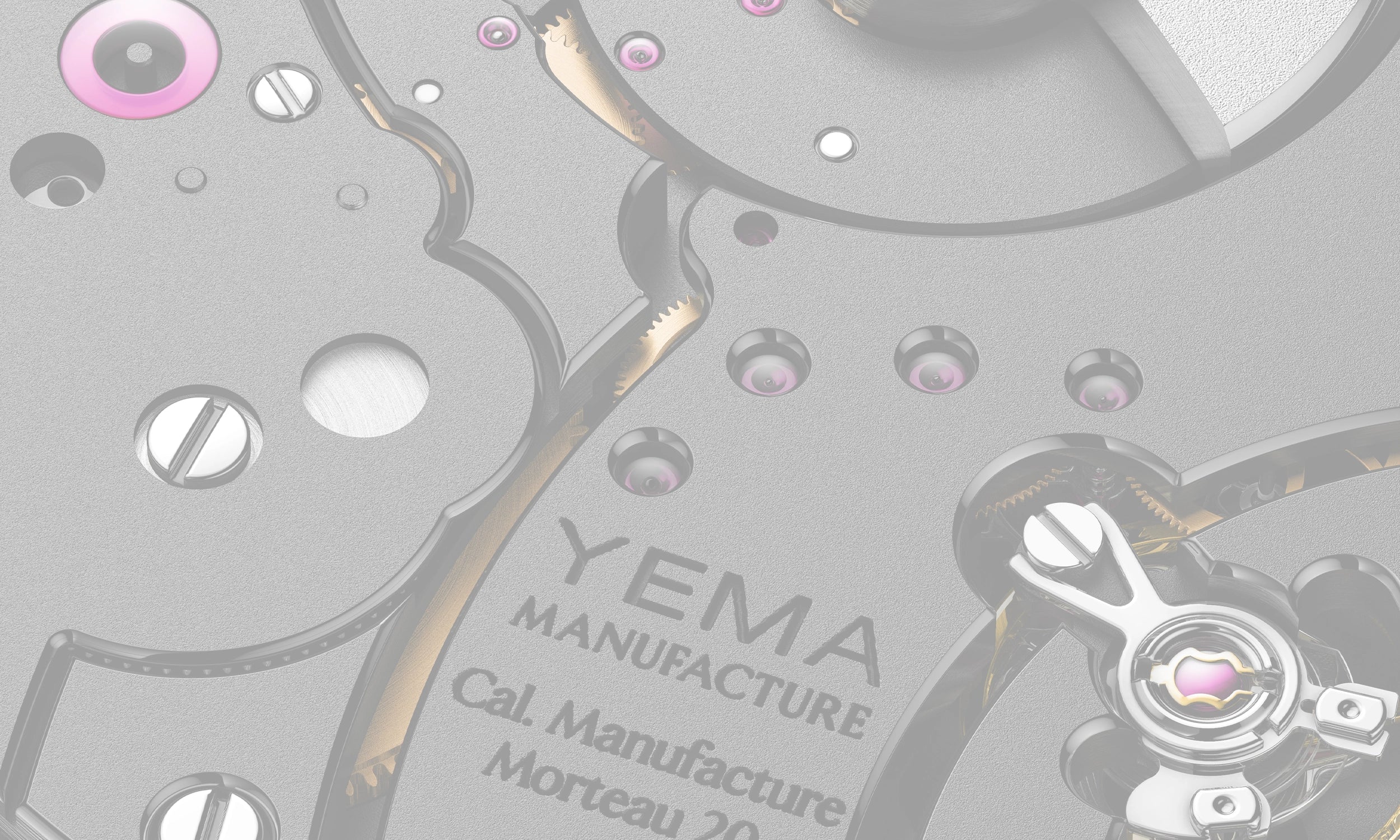

OWN DESIGN LOCALLY MANUFACTURED

The Calibre Manufacture Morteau 20 (CMM.20) micro-rotor unique’s design offers high performance thanks to its clever architecture and high-quality Franco-Swiss components. Entirely designed and developed by Olivier Mory in La Chaux-de-Fonds, the regulating organs are manufactured in Switzerland while the bridges and mainplates are manufactured by YEMA in its Morteau workshops.

3.70mm

ULTRA-THIN CALIBER

Due to its smart architecture resulting in a contained thickness of just 3.70 mm, this new micro-rotor caliber will equip much thinner and elegant cases.

TUNGSTEN MICRO-ROTOR

The bi-directional oscillating micro-rotor winding mass is made of a high density tungsten alloy in order to achieve the purpose of counterweight for this small volume but high weight micro-component, allowing optimized winding and securing a power reserve of 70 hours.

GLUCYDUR BALANCE WHEEL

The balance wheel is made of Glucydur, a non-magnetic, low-thermal-expansion metal alloy which offers high resistant to deformation, corrosion, magnetic fields as well as low coefficient of thermal expansion, most suitable for precision elements that need a lot of dimensional stability.

TALENTED FRENCH WATCHMAKERS TEAM

Four talented French watchmakers, cumulating over 120 years experience at the most prestigious watch brands, have taken up the challenge of creating YEMA’s first Manufacture Caliber

YEMA'S IN-HOUSE WATCHMAKING MACHINING CENTER

During the last two years, YEMA has made substantial investments aimed at insourcing a good part of its production, constantly improving the quality of the manufacturing processes as well as developing a future range of French Manufacture calibers.

This significant development has required substantial R&D, new equipment and the expansion and modernization of our workshops and production lines. YEMA’s Manufacture Calibers benefit from improved precision and performance and will soon equip premium YEMA timepieces.

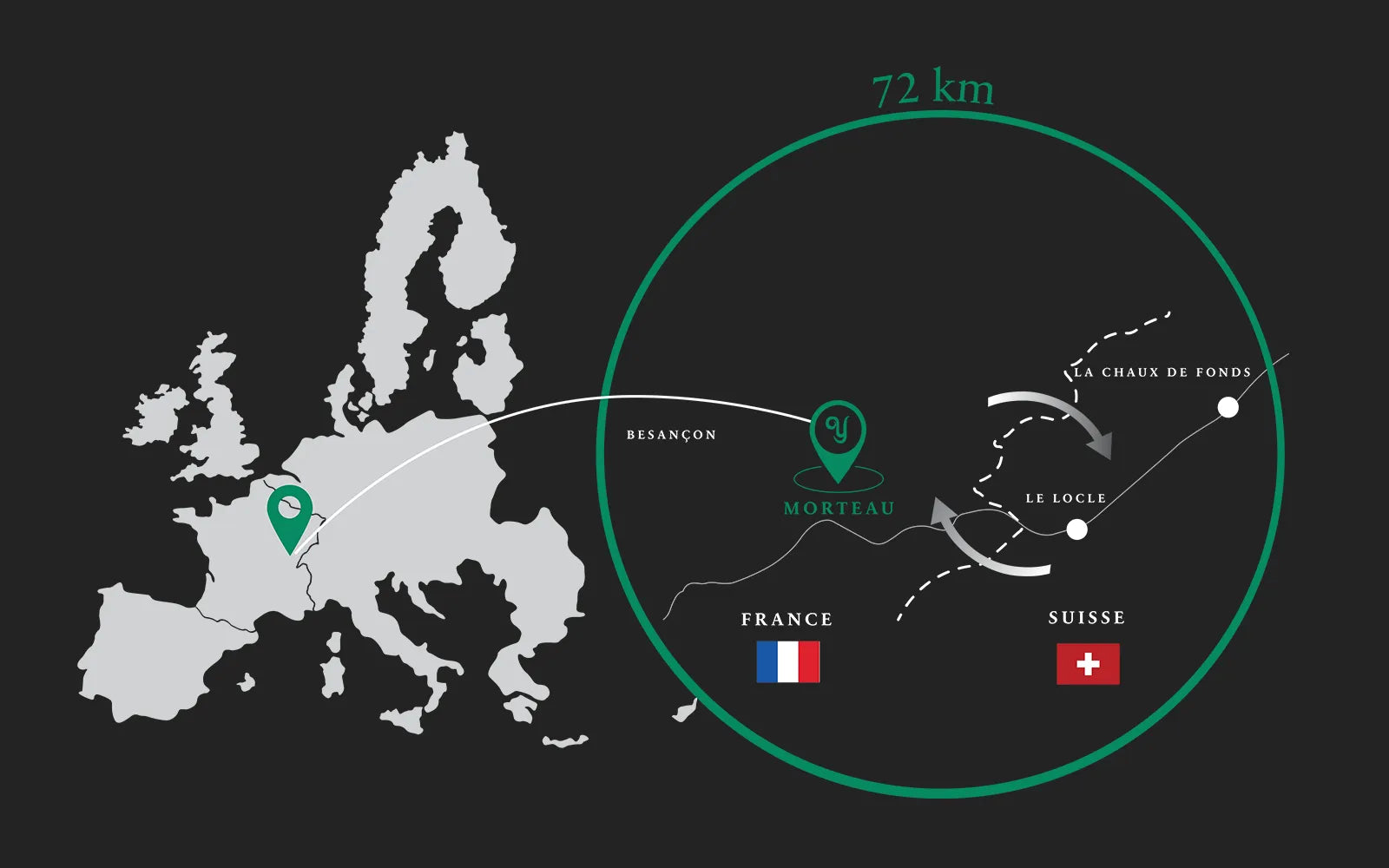

LOCAL PRODUCTION

Over the past few years, YEMA has made significant investments aimed at insourcing a good part of its production and constantly improving the quality of its manufacturing processes by implementing latest equipment as well as expanding and modernising its workshops and production lines.

In addition, YEMA now works with new local partners in France and Switzerland within a range of 72km of its workshops, to secure a more responsible and higher quality production.

Movement Components

All Manufacture movement components are manufactured in France and Switzerland within a range of 72km from Morteau by recognized craftsman in fine watchmaking. The caliber bridges and mainplates are manufactured in YEMA’s workshops in Morteau where final assembly of all components takes place.

COMPONENTS

ORIGINS

Movement Design

Switzerland

Movement Components

France + Switzerland

Assemblies

France

A DYNAMIC REGIONAL WATCHMAKING ECOSYSTEM

YEMA workshops are based in Morteau, the cradle of French watchmaking, a few steps from the Swiss watchmaking region. This cross-border watchmaking community concentrated along the Jura mountains has gradually transformed into a true regional ecosystem recognized as Intangible Cultural Heritage by the UNESCO in 2020.