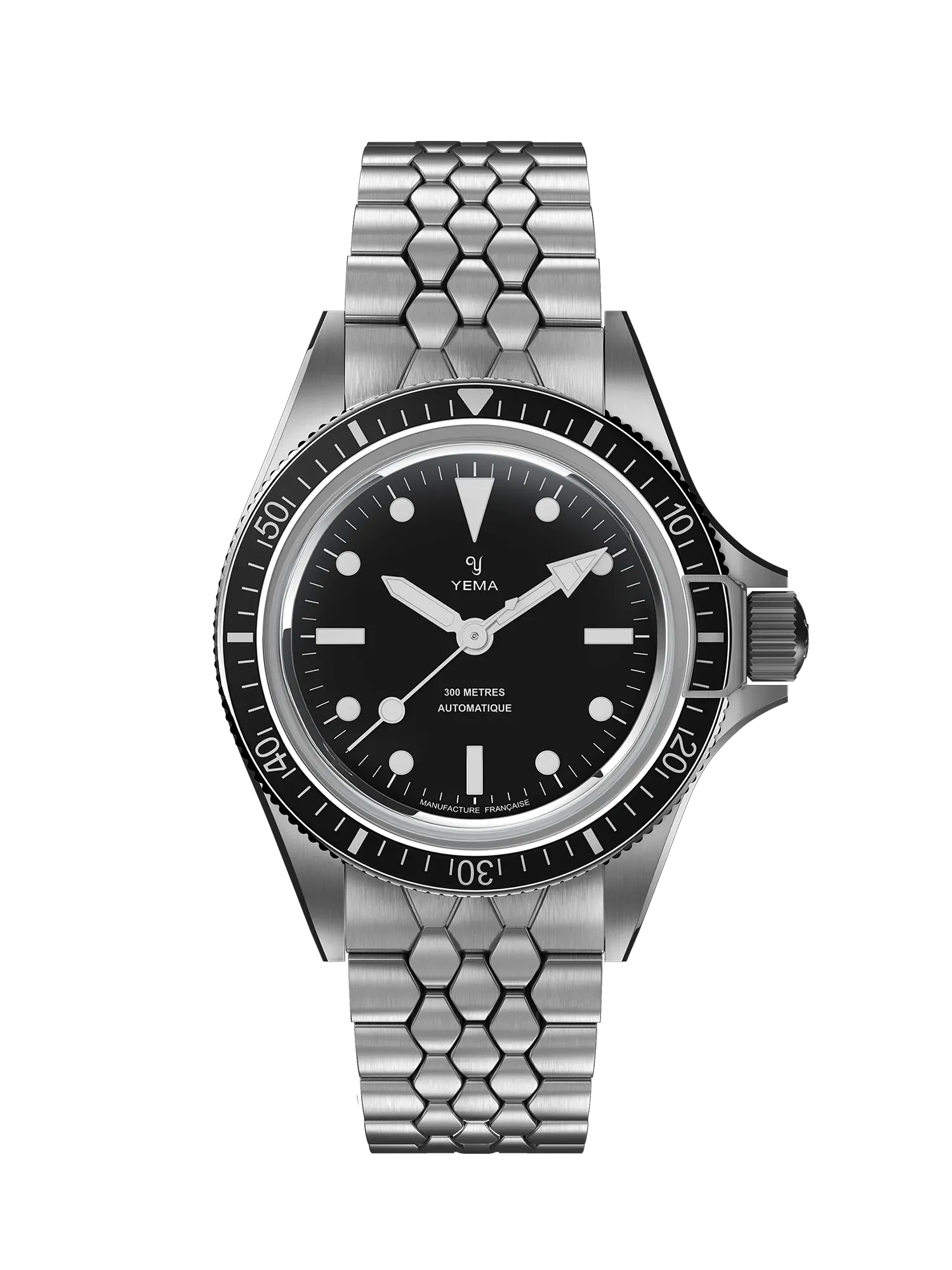

INSIDE THE YEMA MANUFACTURE

The Complete Journey of an In-House Mechanical Caliber

Behind every YEMA Manufacture caliber lies a story of precision, patience, and passion. Conceived by our engineers, machined in-house, decorated by skilled technicians, and assembled by master watchmakers, each movement follows a rigorous path from concept to completion.

This page invites you inside our French watchmaking Manufacture to discover the people, processes, and technologies that give life to our mechanical creations.

Conception

Our proprietary calibers are designed in-house by our team of engineers and master watchmakers. Together they define the movement architecture, design each component in CAD (Computer-Aided Design), and precisely model mechanical interactions to guarantee performance, compactness, and optimal integration of complications.

Prototyping

The first parts are machined in-house one by one and assembled into several functional prototypes. This stage validates mechanical tolerances, overall movement function, and adherence to the technical specifications before production begins.

Reliability testing

An initial pre-series of movements is manufactured in larger volumes to validate autonomy, precision, and shock resistance in real-world wearing conditions. This phase lasts at least 12 months and also harnesses valuable feedback to refine final adjustments and ensure optimal reliability before full series production.

Series production

Using the feedback from the pre-series and testers, certain components may be adjusted or optimized to further enhance performance. Once validated, full production begins, every part is machined, decorated, assembled, and tested according to strict quality standards that guarantee reliable performance across all watches equipped with the movement.

Bridges and mainplates machining

Bridges and mainplates are machined in our workshops with micrometric precision, using high-performance CNC machining centers. This step determines essential volumes, drilling, and locations needed for accurate movement assembly.

Ultrasonic cleaning

Using a next-generation solvent machine, parts are thoroughly cleaned by ultrasonic waves to eliminate polishing residues, oil traces, and dust particles. This ensures perfectly clean surfaces ready for subsequent decoration and finishing.

Dimensional controls

Each part is meticulously inspected using 2D and 3D metrology tools. Our engineers verify critical tolerances to ensure perfect component fit and mechanical reliability of the movement.

Deburring

Sharp edges and machining residues are carefully removed by hand. This finishing step ensures clean surfaces without imperfections, preventing premature wear once the caliber is assembled.

Tribofinishing

Parts are placed in rotating vibratory tubs with a mix of abrasives and additives to perform a gentle, homogeneous polishing. This process smoothes surfaces and prepares components for subsequent decorative treatments.

Microblasting

A jet of microbeads is projected onto the surface of components to achieve a matte, homogeneous finish tailored to the desired aesthetic. The material of the beads (e.g., bronze or silica), their size, and their characteristics are adjusted to produce a refined texture that enhances later decorations. The regularity of the treatment and absence of defects are rigorously controlled to meet watchmaking micro-tolerance standards and ensure optimal light diffusion.

Jewel setting

Synthetic rubies, feet, and pins are installed with micrometric precision using advanced driving equipment. These jewels are essential to reduce friction between moving components and ensure an optimal lifespan for the moving parts of the caliber.

Decoration

Specific surface treatments and aesthetic checks are applied to bridges, mainplates, gears, and rotors. This can include galvanic ruthenium black or rhodium plating, PVD (Physical Vapor Deposition), ALD (Atomic Layer Deposition), sunburst Geneva stripes, and more. Each decorative component is meticulously inspected for finish quality, uniformity, and luster before final assembly.

Riveting and press fitting

Riveting and press fitting are essential assembly operations that join an axle to a plate or wheel to create a cohesive mobile unit. Using a precision press, the axle is driven in under controlled force to ensure perfect alignment and a reliable fit without damaging the components. Riveting then slightly deforms a small excess of material, permanently locking the two parts together so they cannot separate.

Balance staff installation

The balance spring is carefully attached to the balance wheel by a delicate pitonnage process, which ensures regular oscillation of the regulating organ, a critical factor in achieving chronometric precision in the final movement configuration.

Movement assembly

Mechanical components, including wheels, bridges, plates, and springs, are assembled by hand with precision by our watchmakers. This creates the functional heart of the movement. The process follows an electromechanical transfer line (carousel system), guiding each movement step by step through the assembly process in a blend of automation and human expertise.

Precision adjustment

The movement is finely regulated to guarantee optimal chronometric precision. Watchmakers adjust the balance and hairspring, checking daily timing in multiple positions according to high watchmaking standards.

Power reserve testing

This phase measures and optimizes the movement’s autonomy. The mainspring is rigorously tested to verify that it delivers the specified energy, ensuring the power reserve meets technical specifications.

Final aesthetic inspection

After performance validation, each movement undergoes a final aesthetic inspection. Visible components are checked for finish quality, texture uniformity, precise alignment, and overall visual coherence. Only calibers that meet YEMA’s exacting aesthetic and watchmaking standards are approved for final casing.

In our commitment to quality, all timepieces equipped with a mechanical YEMA Manufacture movement enjoy an extended International Warranty period of 5 (five) years.

DISCOVER OUR MANUFACTURE CALIBERS